PP – also known as polypropylene – is one of the most commonly produced and used plastics in the world. It is a versatile polymer which goes into many end-user goods, from car bumpers and pipes to machine parts and most notably, packaging for food and drinks. The versatility of PP comes from it being low density, flexible and easily coloured. This makes it appealing for several aesthetic choices in consumer products.

Buckets

Clean and without contamination inside.

Metal handles are accepted

PP Bumpers

PP/EPDM bumpers from the auto industry

With and without paint

PP Corex

Often known as Coreflute, Corrugated Plastic or Correx

Unfilled preferred, but filled material is accepted if it is not too heavy. Ginger boxes are not accepted for this reason

PP Crates

Automotive Crates, Returnable Plastic Crates (RPCs), Bale Arm Crates, Collapsible Crates, Stackable Containers, Plastic Boxes, Plastic Totes, Plastic Trays

PP Injection Sprues

Injection Moulding Scrap Sprues

Polypropylene Sprues must be separated from any other polymers

PP Pallets

From Distribution, Logistics, Retail, Pallet Leasing, Returnable Pallets or 3PL providers

No 7’s or metal reinforcements not accepted

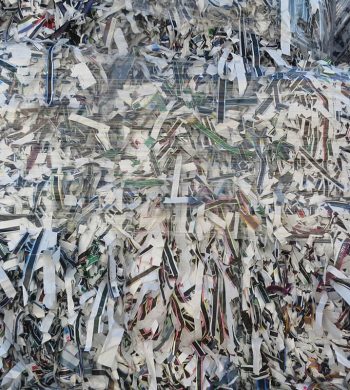

PP Sheets, Offcuts, Trimmings or Skeletons

Sheet or scrap from Thermoforming, Plastic Printing, Plastic Cards or Plastic Label manufacturers.

Trays, Plastic Tubs, Gift Cards, Loyalty Cards, Credit Cards, Horticultural Labels, Plant Labels.

PP Film Printed Rolls or Reels

From Film Extrusion, Film Blowing, Printing or Packaging Industry

On Rolls or Reels, Boxes and Bales

PP Film Trimmings & Print Scrap

From Film Extrusion, Film Blowing, Printing or Packaging Industry

On Rolls or Reels, Boxes and Bales

PP Non Woven

Production Scrap of non woven fabric used in Automotive, Medical, Furniture, Agriculture & Bedding

No silicone or coatings accepted. Cannot be mixed with Nylon or Polyester

PP Bucket Regrind

Clean, Injection grade

MFI testing on every bag

PP Crate Regrind

Distribution Crates, Retail Crates & Manufacturing Crates

MFI testing on every bag

PP Corex Regrind

From Coreflute or Correx used in Distribution or Signage industry

MFI testing on every bag

PP Sheets White Print Regrind

Recycled from extruded sheets from Printing

MFI testing on every bag

Yes. PP Plastic is suited to recycling – especially for post-industrial plastic waste and scrap. The recycling number of PP is 5. Vanden buy, sell and reprocess polypropylene. This makes us well positioned to be part of a closed loop of plastic manufacturing and recycling. We can take your plastic waste and process it into reusable raw material.

Polypropylene is safe to use and reuse. It is an inert material which does not present a health concern, which is why it is often used in food and drinks packaging such as reusable food containers and single use yoghurt pots.

.png)